Category Description

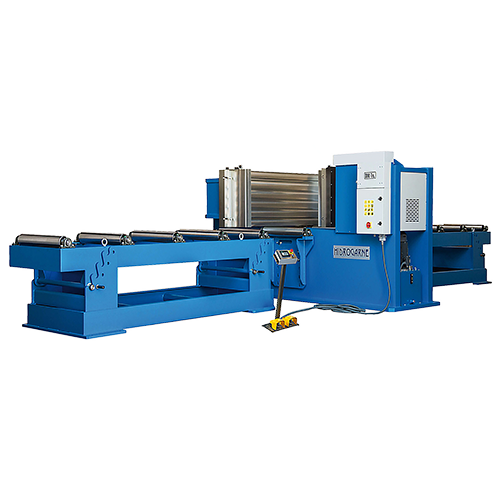

The HV/NC Series Horizontal Straightening Hydraulic Presses are engineered for precision straightening and bending of profiles, bars, and beams. With press capacities ranging from 150 to 300 tons, these machines combine durability and versatility, offering advanced functionality through optional tooling and Industry 4.0 compatibility. Designed with a robust horizontal configuration, they simplify handling of large components, ensuring high performance and operational efficiency.